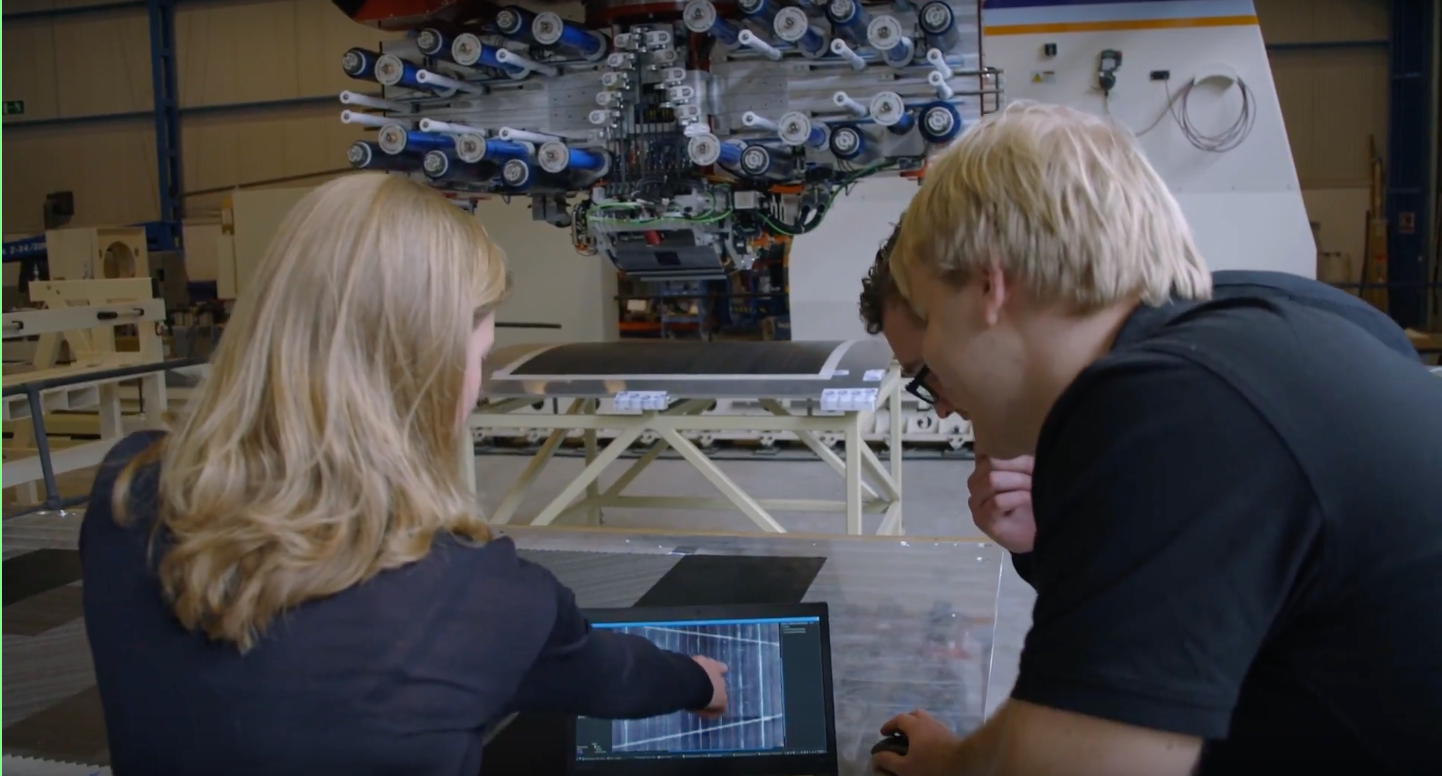

We offer sensor systems for Automated Fiber Placement (AFP) and Automated Tape Laying (ATL) machines for real-time, in-process monitoring. Our solution enables fast and reliable detection of non-conformities, reducing time effort for manual inspections and eliminating cost of non-quality. Each sensor is optimized for each machine and application, while our post-processing algorithms and interfaces are generalized to unify inspection workflows shop-floors with various machine types.

Overview

Application

The high level of integration into the machine cells and synchronization of sensor and machine data enables various applications:

- Precise, localized and real-time detection of layup defects

- 3D reconstruction of the as-manufactured position/ angle of each individual tow or ply contour

- Assistance in first article inspection and qualification

- Predictive maintenance by monitoring the machine performance over extended periods

Our systems are compatible with both robotic and gantry-type AFP/ATL/winding machines of all common suppliers, as well as with a wide range of thermoplastic and dry-fiber materials.

Specification

- Detection of Gaps & Overlaps, Twists, Dropped Tows, Splices, Fuzzballs and Wrong Cuts/ Adds

- Scanning width: 50-350 mm

- Scanning frequency: >1 kHz

- Resolution: 20 μm (height) and 100 μm (width)

Innovation

We are continuously improving the capability and performance of our systems on all aspects, adapting promising technologies from other sectors and academia to our needs. With our fiber-layup monitoring sensors, we are engaged in various national and international research projects, striving to find the absolute best solution for a problem.