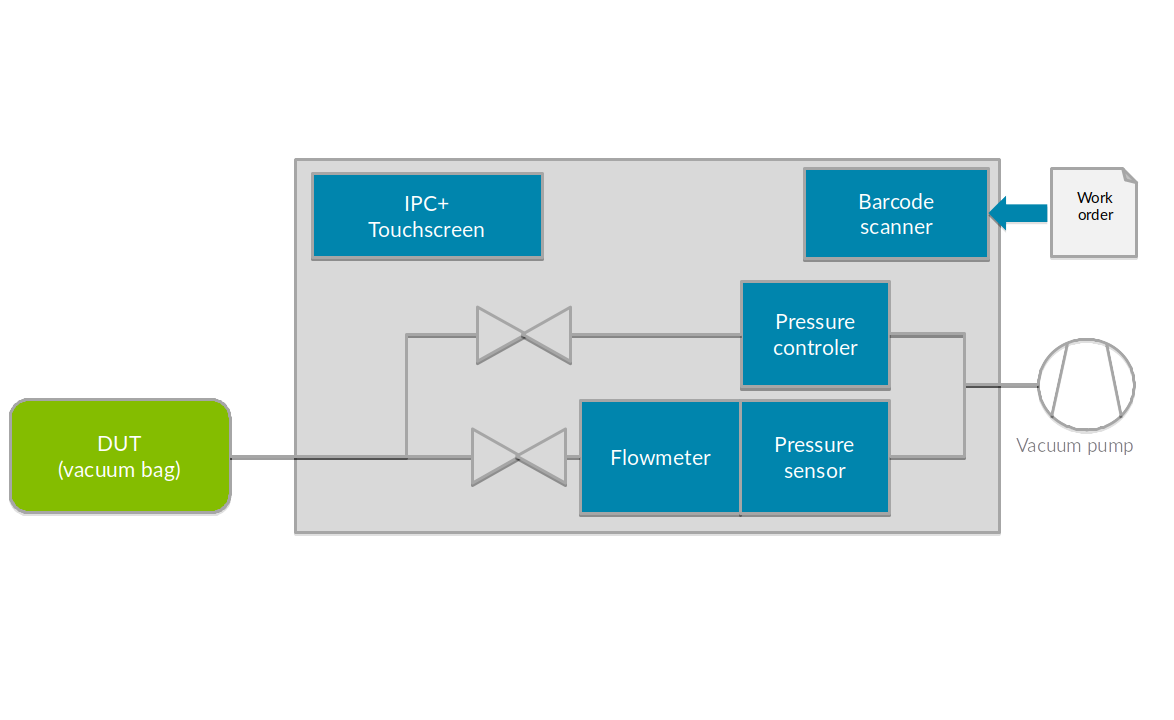

Our leakage detection system allows a fast localization of leakages in vacuum setups and enables more efficient bagging of composite parts.

- Reduced processing time through fast leakage localization

- Parallelization of processes through automatic vacuum assessment

- Data continuity through part-related data storage

- Facilitated bagging through integrated vacuum control function